Shon Isenhour

Recent Posts

The Victimization of Maintenance

FMEA, and RCA, Got You Overwhelmed, and Paralyzed?

I get it, Failure Modes Effects Analysis (FMEA) and Root Cause Analysis (RCA) are hard or at the very least hard to execute consistently. If you look at the amount of them that you need to do or should do, it can be quite overwhelming. Many sites get paralyzed by this and do very little or nothing with these very important tools. Just like many of the other elements we talk about that are needed...

Is Your Predictive Maintenance Program a Rifle or a Shotgun Approach?

Is your predictive maintenance program setup like a rifle or a shotgun? Would you say it is well thought out and directed at a specific failure mode of a known risk or is it more of a shoot and scatter and see what I can hit approach?Over the last few years I have seen more sites that are the later more than the former. They hand out PdM tools to untrained or minimally trained technicians,...

Seriously, It Is Time To Plan

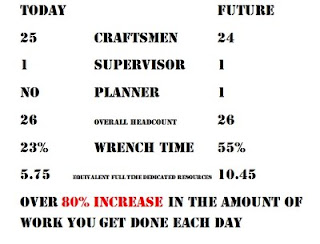

Never Met a Maintenance Manager that had Enough People

Of all the sites I have been in all over the world, I have never met a maintenance manager who said to me “You know Shon I just have too many people.” In fact most ask me how they should go about bringing more into their fiefdom. It usually sounds a bit like this: “I need to hire planners, supervisors and a few more crafts in order to improve my reliability. If I could get support for more I...

Five Whys and Wishbone: Program and Training Sponsorship

Over the years I have seen many sponsors give great supporting speeches but I have also noted a few that failed miserably along the way. Lets learn from them. One in particular was the kick off of a new root cause analysis facilitators program in a facility with a history of " flavor of the month" programs and lack luster performance. The "leader" did not attend the workshop because he was...

Laser Focused Turbo Implementation: Throwing the BS flag again

We live in a world where we are constantly sold silver bullets, magic pills, and laser focused turbo implementations. When in reality it takes focus, time, knowledge, and grit to implement organizational change. If someone promises you instant implementation, throw the BS flag. (If you don't have one let us know, we have plenty.) Real change takes more than a few weeks; no matter how many...

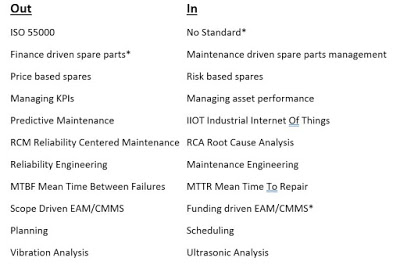

What Is In and Out In 2018: The Maintenance and Reliability Edition

As James Kovacevic and I sat around and talked about trends in Maintenance and Reliability going into 2018 we noticed that we could see some elements that had fallen out of favor in 2017 (at least in North America) and others that have become the hot new thing. Out of that became the list you see above. Many of the decisions have been driven by the return of manufacturing demand and the need to...