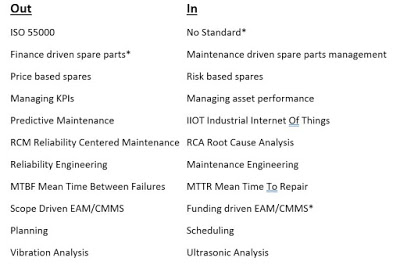

As James Kovacevic and I sat around and talked about trends in Maintenance and Reliability going into 2018 we noticed that we could see some elements that had fallen out of favor in 2017 (at least in North America) and others that have become the hot new thing. Out of that became the list you see above. Many of the decisions have been driven by the return of manufacturing demand and the need to meet customer orders. For example, many organizations have lost focus on Mean Time Between Failure and have instead decided to focus on Mean Time To Repair. In other words, they are focused on getting the asset back up and running quickly and not preventing the failure from happening to start with or preventing it from reoccurring. Others have given up on truly planning jobs and PM task and instead are just guessing at a schedule or “filling” the hours available. Many organizations are driving toward the more reactive choices “in order to meet demand.” With the exception of the items with an asterisk above, the items on both sides are the right choices if they are applied at the right time. You need all of them working in concert as part of a comprehensive plan to increase up time, reliability, and throughput. If you would like help building a plan for your organization reach out to us and let us show you how others are progressing with all of the elements in the right order and at the right time and avoiding the temptation to chase the shiny new silver bullet.

For more blogs like this, be sure to visit Shon Isenhour's blog: www.reliabilitynow.com