Eruditio's Implementation & Training Manager, Rick Clonan was named in the first group of the top 100 maintenance influencers to follow on LinkedIn. Sharing his experience, insight, and industry hot topics are a few of the many areas his promotes on his page. Read more by visiting: 100 People in Maintenance That You Should Follow.

Rick Clonan Named in Top 100 Reliability & Maintenance To Follow

Reliability Engineering planning and scheduling maintenance maintenance engineer Reliability professional

Read MoreSeriously, It Is Time To Plan

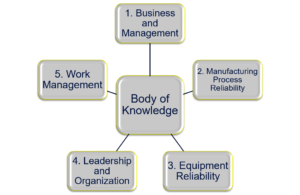

Understanding the SMRP Body of Knowledge

In preparation for our next SMRP Body of Knowledge Review workshop coming up June 19-21, James wrote an excellent blog post on understanding the SMRP Body of Knowledge.

Who Owns Equipment Reliability?

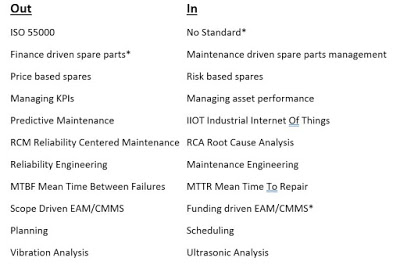

What Is In and Out In 2018: The Maintenance and Reliability Edition

As James Kovacevic and I sat around and talked about trends in Maintenance and Reliability going into 2018 we noticed that we could see some elements that had fallen out of favor in 2017 (at least in North America) and others that have become the hot new thing. Out of that became the list you see above. Many of the decisions have been driven by the return of manufacturing demand and the need to...

10 Tips for Getting the Most Out of Your Next Maintenance Assessment

Another great blog post from James Kovacevic:

Assessments are a key tool for driving sustainable improvements in you Maintenance, Reliability, or Asset Management program.

When you hear the work assessment or audit, does it send shivers down your spine? Do you envision a week or two of some “expert” digging through your data, processes, and performance, looking to get you in trouble for something...

A Balanced Improvement Strategy

Three reasons why I detest "wrench time" as a benchmarking tool.

Ranting about Reliability:

Wrench time and wrench time studies are two of the most misused, misunderstood, and painful to deal with elements of maintenance benchmarking for three reasons:

- different definitions and standards

- data that is skewed by the act of collection

- overzealous comparisons of dissimilar metrics from different locations

We all like the implications of knowing the amount of non...

3 Reasons Why Operations Does Not Support Maintenance and Reliability

One of the most common things maintenance folks say is that operations does not support maintenance and reliability. It sounds like this:

"If it weren't for operations we would be reliable"

"They think their job is to break it and then it is our job to fix it... and fast"

"They will not let us have the equipment for PM and they wonder why it breaks down"

Want to know what operations has to say?...