Shon Isenhour

Recent Posts

Education Without Application Is Just Entertainment: 3 things that can help create a return on education.

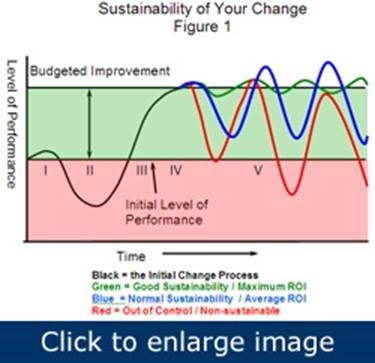

Five elements of sustainable cultural change

Change dynamics, leadership, risk identification and management, communication, and project management all must be addressed.

By: Shon E. Isenhour

A Valentines Day Message About Mismatched Communication

Mismatched communication plagues a lot of organizations and affects the implementation of new initiatives and organizational changes. This video shows a demonstration of the concept.

Thankful Thinking: 7 List of Thanks

Is The MTTR Metric Killing Your Reliability?

Not Running From the Saber Tooth Tiger: Reactive to Proactive Leadership in 3 Steps.

Five questions you have to answer before your next change initiative.

We all are part of change initiatives and interestingly the majority of them fail to deliver the results expected or projected. When we look back at the ones that failed to deliver, we find many that were destined to fail from the beginning because of the way the change was unveiled and communicated to the affected individuals. Below are five question that are crucial to answer upfront,...

Four -isms That Might Be Killing Your Reliability

Lets talk today about the four -isms that may be running around in your plant and limiting your ability to improve up-time, quality and reliability. The first step is to recognize that they exist and then we can determine a plan to mitigate or eliminate it. Below I have given you the four as well as a sound bite and possible mitigation strategies. It is best if you can prevent them from rearing...

Stop Corrective Maintenance Repairs on Preventive Maintenance Work Orders.

4 Simple Steps to Start Creating a Learning Culture in Your Organization

Is training a drudgery endured once or twice a year or is it a part of daily life enjoyed by all? Many companies and sites are missing the boat by not having a culture of continuous learning. One where new knowledge is constantly entering the "collective" and finding its way into use. If you can create this culture then you will keep your organization competitive while improving morale according...