More is not necessarily better when it comes to preventive maintenance you have to find the right amount done right with the right tools.

More Preventive is Not Necessarily the Answer

Nine "Ps" for Profitable Plant Reliability Improvement Efforts

So if you could sum up the common areas of focus during reliability improvement efforts what would they be?

The thought behind this blog post was if someone ask us what we are doing or what all is involved in a reliability improvement effort, how can we give them the scope in a concise, and memorable way. This could be used early on in the discovery or kick off phase to outline without...

FMEA: Its Not Just for Maintenance Anymore

Reliability Begins with Effective Job Plans: A guest post from Coach Allen Canaday

Are you still using a job plan that doesn’t contain performance standards for proper work execution? You know, performance standards, the technical information the job plan conveys to the technicians performing the task. This is the specific knowledge required in order to ensure the step is completed without introducing an error or failure. I’m talking about such “trivial” information as torque...

Is The MTTR Metric Killing Your Reliability?

Not Running From the Saber Tooth Tiger: Reactive to Proactive Leadership in 3 Steps.

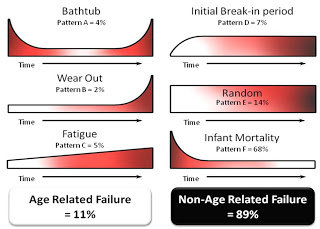

Failure curves and P-F intervals linked and explained: Tying the two most important reliability engineering curves together to generate a better picture of failure

During the early development of what would become Reliability Centered Maintenance, Nowlan and Heap gave us six failure curves to the left. When folks first see that sixty eight percent fall into the infant mortality curve then the doubt fairy tends to show up. "Sixty eight percent of the failures in my facility are not instant or early on start up." With this thought they then discount the...

Preventive Maintenance and Exercise: Three ways they are the same and one way they are different

Preventive Maintenance can be a lot like exercise but we will talk about just three of the ways they are the same and one major difference in today's post. The three ways they are the same include the following: Both of them can prolong the life of the asset. That asset may be a body or a machine but by doing the right activity at the right time it gives you the improved reliability that you...