Installing an asset is a critical step that can impact reliability short term and long term. Often times assets are installed without much thought. They are thrown on the machine base, anchors drilled and away the operation goes.

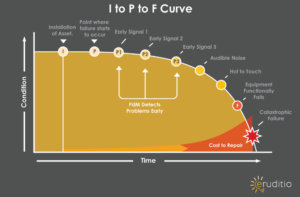

But while focusing on the Installation – Potential Failure – Failure curve, it becomes obvious that time and precision during the installation point can greatly extend the life of the asset. By investing in the installation, the asset will experience less premature failures and extend any wear out mechanisms that are present in the asset.

Ensuring that the machine base is correct, can be addressed through three distinct areas.

Foundations

Form the basis of all machinery installation. The foundation is a structure used to receive and transfer to the ground the static load from a machine and the dynamic loads imposed during the operation of the machine as a result of imbalances in the moving parts. Since the foundation is critical, the foundation should be designed and built according to the approved engineered drawings. However, sometimes there may not be access to an engineer or drawings, and the foundation must be designed in the field. Instead of approved drawings, there are some basic rules of thumbs which can be observed;

|

Foundation Size |

Exceed machine base by 150mm on all sides |

|

Mass of Foundation for Rotating Equipment |

3x Machine Mass |

|

Mass of Foundation for Reciprocating Equipment |

5-8x Machine Mass |

Machine Anchors

The method in which the machine is anchored to the foundation is vital. Depending on the type or method of anchoring anchor bolts, there are different requirements to ensure that the anchors provide the right amount of hold down force. Fixed Anchor bolts are used to secure large equipment and are fixed directly into the concrete foundation; their holding force depends highly on how deep they are installed into the concrete. The other types of anchors include Pipe (Tube) anchors, boxed anchor bolts, mechanical expansion anchor bolts or chemical adhesive anchor bolts. These types of anchors are typically installed after the foundation has been cured. Depending on the type of anchor used, the depth of the anchor bolt installation should meet a minimum installation depth;

|

Fixed Anchor Bolts |

Other Anchor Bolt Types |

Minimum Installation Depth |

||

|

Type |

Minimum Installation Depth |

|||

|

Straight Anchor Bolts |

25x Diameter of Anchor Bolt |

Pipe (Tube) Anchor Bolts |

Per Manufacturer Instructions |

|

|

Bent Anchor Bolts |

4x Diameter of Anchor Bolt |

Boxed Anchor Bolts |

Per Manufacturer Instructions |

|

|

Straight Anchor Bolts with Plate Washers |

4x Diameter of Anchor Bolt |

Mechanical Expansion Anchor Bolts |

Per Manufacturer Instructions |

|

|

Chemical Adhesive Anchors |

4.5x Diameter of the Anchor Bolt |

|||

Also, the spacing of the anchors is critical to ensuring that the anchors can support the loads and prevent damage to the concrete. Below are the generally accepted spacing of anchors;

|

Spacing From |

Minimum Spacing Distance |

|

Next Anchor |

10x Anchor Bolt Diameter |

|

Unsupported Edge of the Foundation |

5x Anchor Bolt Diameter |

Machine Base Flatness

The machine base must free of corrosion, damage, and flatness. The base plates should be measured for level, flatness, and coplanarity. The machine base should be leveled to plane in parallel to the plane of the earth’s surface. Flatness is measured only in the area where the machine will be mounted to the base plate. Flatness can be achieved through machining or shimming. Coplanarity is ensuring that two individual base plates are parallel with each out, with no angularity. The degree to which a base should be level, flat and coplanar depends on the size of the equipment. Listed below are the acceptable specifications

|

Machinery Type |

Minimum Recommended Levelness |

Minimum Recommend Foot Flatness |

Maximum Coplanar Surface Deviation |

|

Machinery up to 500HP |

0.010 thou /ft. |

0.005/ft. |

0.002 thou/ft. |

|

Machinery above 500HP |

0.005 thou/ft |

0.002 thou/ft |

0.002 thou/ft |

Making it Work

Machinery installation should be proceduralized so that the installation is performed to the same standard every time it is done. This involves developing standards for specific tasks, training the staff on the process and standards and finally ensuring that any contractors follow the same standards. It is only by using standards and procedures, can organizations ensure that machine bases are properly designed, and equipment installed correctly on them.

Do you have machinery installation standards? What is stopping you from extending the life of your assets through proper installation? If you need assistance in developing, understanding and applying proper machinery installation, please contact jkovacevic@eruditio.com for additional information.

I’m James Kovacevic

Principal Instructor at Eruditio

Where Education Meets Application

Follow @EruditioLLC

Follow @ReliableJames

Follow @HPReliability