Jon Bailey

Recent Posts

12 Days of Shutdown

Software Got You Stuck? Do Not Let RCA Applications Hold Up Your Root Cause Efforts

Let us be clear, root cause analysis is a way of thinking not a software application yet their are sites that are spending thousands of dollars and hundreds of hours learning software instead of solving problems. Software is not inherently bad but you don't need a sports car to learn to drive. If you are getting started with your RCA efforts and software is part of your plan then be aware of...

Back To The Future...But Stuck In The Past

Click here to see an inspiring message from Doc Brown himself: The future has finally arrived Here are some thoughts on the matter from our lead coach Brandon Weil:

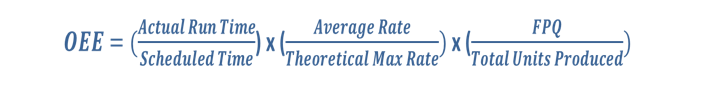

3 Steps to Turn OEE into a Financial Indicator

Overall Equipment Effectiveness (OEE) is undoubtedly one of the best indicators of process reliability, but many struggle to connect OEE to the bottom line. How much of an OEE improvement is necessary? How aggressive does my reliability improvement program need to be? Turning OEE into a financial indicator helps us translate these questions into business decisions.

I Wish My Boss Were Here For This Training!

I hear the title quote "I wish my boss were here for this training" or "My boss needs to hear this" after almost ever training session we do. Sometimes it is a leadership or communication class other times it is reliability or manufacturing improvement sessions but the response is nearly the same every time. I take this quote to mean at least two things:

Congratulations to eStudios!

We are proud to announce that our production studio, eStudios, has won a Telly Award for a humorous video they created about a company's biggest competitor - doing nothing. Staying complacent is is a dangerous and costly way of thinking, and in this slapstick infomercial, we highlight the absurdity of this commercial with the absurdity of actually doing nothing.

Why eLearning Is Your Best Choice

A lot of people are wondering about this new educational phenomenon called eLearning. As technology changes, so does the world, and it is only fitting that the way we teach and learn would evolve with those changes. If you think about it, education has changed very little over the past 5,000 years. A professor teaches a class of students face-to-face. They use books, they write things down on...

Strategies to Survive the Skills Gap

Use technology and human resources approaches to mitigate the effects of the retirement of trade professionals.

Two Things Engineers Consistently Get Wrong

As I think back over the years of site assessments, reliability implementation, and coaching of facilities and engineers globally there are two concepts that consistently show up as weak areas with engineers in manufacturing environments. The first is true in-depth "root causes" problem solving (this is different than the "engineers jumping to conclusions process" that many employ) and the second...

What Is A Flipped Classroom?

The flipped classroom is a what is known in education as a pedagogical model in which the typical lecture and homework elements of a course are reversed. Short video lectures are viewed by students at home or work before the face to face class session, while in-class time is devoted to application exercises, projects work, or group discussions. The video lecture or elearning is often seen as the...